SiMP 2K 50LV | Low Viscosity Two-Component Flexible SiMP Adhesive

SiMP 2K 50 LV is a flexible, two-component adhesive with low viscosity, based on Silyl Modified Polymer (SiMP). After mixing, the adhesive cures to form a high-performance bonding compound with wide adhesion to industrial materials. It is solvent-free, isocyanate-free, and odorless. The low viscosity of the adhesive allows application on surfaces using spraying methods (with specialized equipment), rollers (with adhesive machines or manually), and brushing. Despite its low viscosity, the product ensures quick initial adhesion.

-

Environmentally friendly, solvent-free and isocyanate-free, no hazard warning symbols required

-

No bubble formation – Odorless

-

Even curing through volume, even between non-porous materials and at low temperatures

-

Permanent flexibility across a wide temperature range

-

No volume change – No shrinkage

-

Low viscosity – easy application by spraying, wiping, or rolling

-

Non-sagging when applied vertically, with fast adhesion effects

-

Excellent adhesion without the need for a primer on all common construction and industrial materials

-

Fast strength development

-

Neutral properties, safe for the substrate surface

-

Impact and vibration resistance (shock absorption)

-

Spot welding can be done before curing

Application

SiMP 2K 50 LV ensures high performance for all applications requiring permanent flexible elastic bonding surfaces in industrial and interior fields, panel assembly, insulation and refrigeration, transportation (automotive body, refrigerated trucks, containers), railways, and marine industries, as well as in general assembly and other applications.

Thanks to its rapid crosslinking capability, parts can be bonded in a continuous working process. SiMP 2K 50 LV can be used on metal surfaces, electrostatic coatings, painted surfaces, galvanized, anodized, chrome-plated, or hot-dip galvanized materials, plastics, ceramics, stone, concrete, and wood. Due to the variety of materials and components, preliminary adhesion testing is recommended.

Compliance

LEED iEQc 4.1; SCAQMD Rule 1168; BAAQMD Reg 8 Rule 51

CARB VOC levels regulation

Certification

EMICODE EC 1PLUS protocol

EUROFINS IAC GOLD protocol

VOC Emission class label A+

Technical Data

TECHNICAL DATA components

|

Chemical nature |

SiMP – Silyl Modified Polymer Hardener |

|

Appearance |

Low viscosity paste Liquid |

|

Color |

Grey Grey |

|

Densitiy [g/cm3] |

ca. 1.5 ca. 1.38 |

|

Mixing ratio (volume) |

3.64 1 |

|

Mixing ratio (weight) |

41 |

TECHNICAL DATA mixed product

| Appearance | Low viscosity paste |

| Color | Grey |

| Chemical nature | SiMP – Silyl Modified Polymer |

| Densitiy [g/cm³ (NPT method 03) (23°C and 50% RH) | ca. 1.48 |

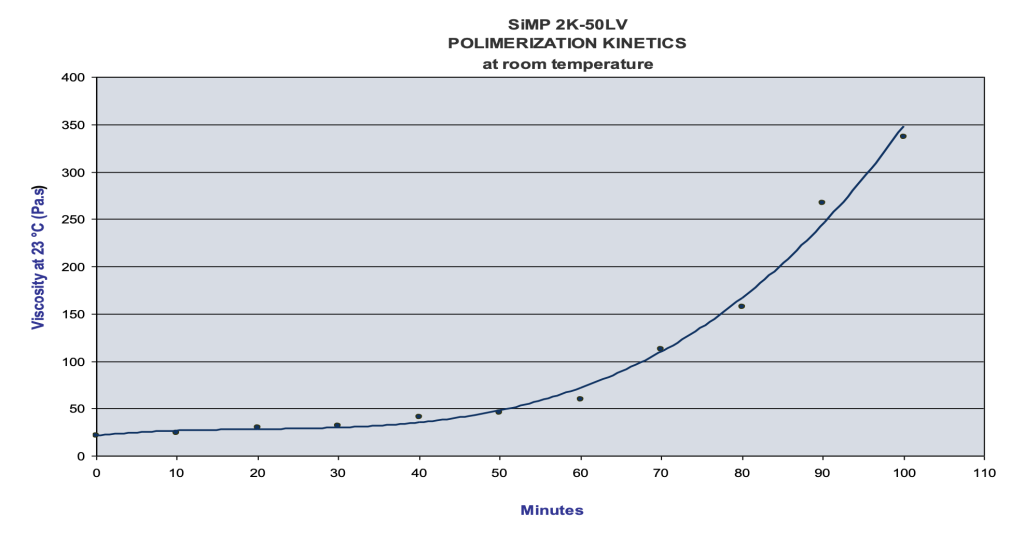

| Pot life [min] (23°C and 50% RH) | ca. 50 |

| Handling time [min] (23°C and 50% RH) | ca. 20 |

| Full hardening time [h] (23°C and 50% RH) | ca. 24 |

| Hardness Shore A (DIN 53505) | ca. 30 |

| Tensile strength [N/mm2] (DIN 53504) | ca. 1.7 |

| Elastic modulus [N/mm2] (DIN 53504) | ca. 1.5 |

| Elongation at break [%] (DIN 53504) | ca. 130 |

| Application temperature [°C] | From +5 to +40 |

| Temperature Resistance [°C] | From -40 to +90 |

POLIMERIZATION KINETICS

Instructions for Use

Surfaces to be bonded must be thoroughly cleaned, dry, and free from dust or grease. Pre-treat the bonding surface according to NPT’s application guidelines, and use a specific CLEANER or ACTIVATOR from NPT’s product line. Preliminary adhesion testing on the supporting surface is recommended.

Prepare a mixing container with enough capacity to hold both components in the desired total amount. Pour the ratio of 1 bottle (1.25 kg) of Component B for every 5 kg of Component A. Do not mix more than the required amount, as unused material will cure during the application time and must be disposed of. Mixing can be done with electrical equipment using a dedicated mixing device. Ensure the mixture has a uniform color; poorly mixed material should not be used and must be discarded. Parts must be assembled during the application time, with even pressure applied across the entire bonding area. Avoid contact with solvents during curing.

Cleaning Instructions

Clean used tools with acetone or solvent. When the adhesive is uncured, it can be wiped off with paper or cloth. Once cured, the product can only be removed mechanically. Avoid direct skin contact by wearing latex, rubber, or polyethylene gloves. If the adhesive contacts skin, remove immediately and wash with soap and water.

Storage Instructions

SiMP 2K 50 LV can be stored for 12 months in its original (unopened) packaging at temperatures between 10°C and 25°C in a dry, cool place. The storage temperature should not exceed 25°C for extended periods. Keep away from damp areas, direct sunlight, and heat sources.